The days of 3D-printed jewelry seeming like a sci-fi movie concept are passed. Today, an increasing number of jewelry makers print their creations. Because 3D-printed jewelry looks and feels just like conventionally cast products, it is on the approach of becoming commonplace. Let’s examine more closely at this design revolution.

Is Additive Manufacturing a good fit for your jewelry production? Or perhaps you don’t have a jewelry business and want to establish one. In any case, it may be of importance to you to understand that 3D-printed jewelry is a genuine thing on the market.

Things You Required!

source: pinterest.com

Because 3D printing encompasses so many diverse technologies, there is no single, simple answer. Even though some printers employ filament, some require powder and others choose wax/liquid resin.

All 3D printers, meanwhile, have one feature in common: they require a 3D file. This 3D file contains information & data on the stuff that the printer is required to print. Special 3D modeling software is used to create 3D files. These applications vary from beginner-friendly free modeling tools like Tinkercad to high-end jewelry-making programs like RhinoGold.

Once all the 3D file has been prepared, the printer may use it to manufacture a genuine physical thing. The creator does not even need to possess a 3D printer if he or she uses online 3D printing tools like i.materialise.

Latest 3D-Printing Technology:

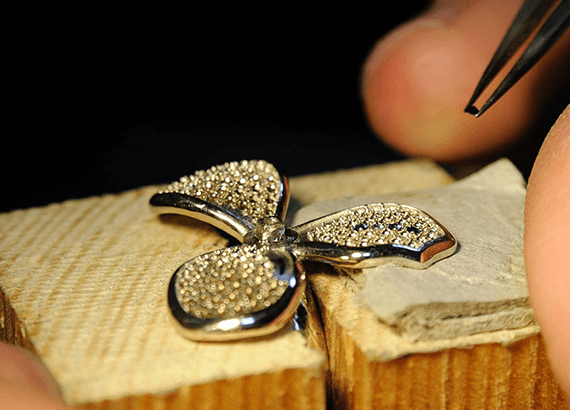

They employ Lost-Wax Printing and Casting to make jewelry in platinum, gold, copper, silver, and bronze. This method is based on both current 3D printing technology and traditional metal conjuring.

The process begins with designing and producing your 3D model in wax. As a printing rule, the 3D printer involves a wax-like resin. The sculpture will then be fitted with one or more wax flocculation. The sprue will then connect your figure to a wax ‘tree,’ along with numerous other models. After that, the tree is taken in a beaker and coated with the finest plaster. After that, the plaster mold is placed in an oven and baked for many hours until the wax is fully burnt away.

Perks & Drawbacks Of 3D Printed Jewelry:

source: instoremag.com

Bracelets, necklace links, and other jewelry pieces are made by melting precious metals like gold and molding them in a conventional mold. To work more effectively, jewelers have already been printing the casting mold in 3D. The molten precious metal is then mixed thoroughly to solidify. To gain a first (physical) impression of the gem, a preliminary version can be created in 3D.

The perks of 3D printing involve:

- Prototypes are much less expensive.

- Print in any shape you can think of using a variety of materials.

- There is less material wastage.

- The jewelry is perfectly symmetrical.

- Your jewelry is handcrafted to perfection.

Alas, a few drawbacks are:

Printing takes a long time.

Certain printing supplies are exorbitantly priced.

To create the right item, your goldsmith must be very competent.

What About Cost!

source: zortrax.com

That is a tricky matter. The cost of a 3D print is primarily determined by its dimensions, weight, and, most crucially, its component. As a result, each design has its own pricing. You must upload a 3D file to the estimating platform or jewelry printing center in order to receive an exact price. You will immediately see how much it will cost to print your design with every material and polish.

Innovative 3D Printed Jewelry Design:

There are currently several outstanding 3D printed jewelry designs online, such as Nylon 3-dimensional printed bracelets, fancy rings, and a versatile clutch. However, we keep an eye on the most recent initiatives because new ones emerge all the time and are extremely inspirational.

3D Wave Encode Ring

3Dwave, a Japanese firm, has designed a collection of 3D-printed jewelry rings. You simply send a 3-second audio sample to this creative collection, and they will transform it into a magnificent 3D printed ring. This cutting-edge technology allows music to be translated into a 3D model file that can then be generated. These rings are available from 3Dwave in a variety of metals, including valuable metals like platinum and gold.

Nest Pendant

source: fabbaloo.com

Custom printing is one of the most renowned websites for high-quality 3D printers, so it’s not surprising that they also have a high-class area of 3D-printed jewelry. His adorable little inclination is one of the most alternative methods on their website.

Nervous System

Nervous System creates stunning, nature-inspired constructions with arrays of rings, pendants, and coordinating earrings that would be hard to build without 3D technology. To generate those beautiful patterns, they employ computer models of flowers, such as leaflet venation. Is it possible that your idea for 3D-printed jewelry is just next to you? Take a close look!

Paola Valentini

source: 3dprintingindustry.com

Paola Valentini’s 3D printed jewelry was deemed so lovely that it was just given the highest design prize by the Comité Francéclat. Valentini’s 3D printable rose gold cuff bracelet won the award, with the complicated structures of the 64-gram piece created utilizing additive manufacturing processes.

Future Of the Jewelry Industry!

The future of customized fine jewelry is 3D-printed jewelry! Straightforward precious metal 3D printing technology allows for the creation of one-of-a-kind designs, minimizes resources, is a significant step toward a zero-waste sector, and allows buyers to have customized jewelry rather than other stuff that is marketed to everyone.

Additive manufacturing procedures (also known as 3D printing) ensure quality standards equivalent to those attained using traditional production techniques, save time and money, need a minimal diverse workforce, and have nearly no environmental harm.