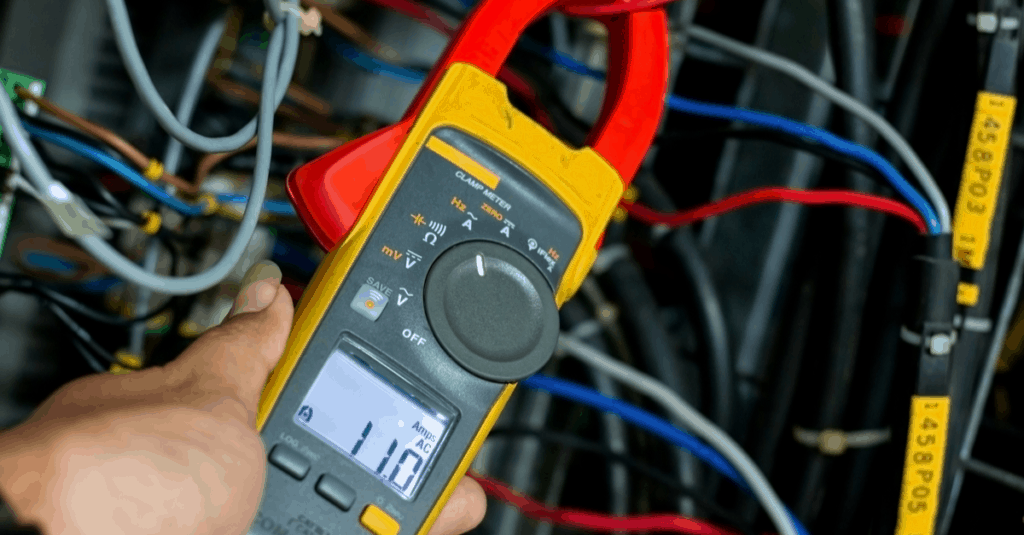

What Do We Know About a Current Clamp?

A current clamp is a highly beneficial electrical appliance used for gauging the current that flows through or within any conducting medium. The measurement gets done in amperes. The device comes with a pair of jaws. They can open up and hold onto or clamp a conductor during the quantification process. It allows it to calculate the current flow and display the evaluations or readings immediately. The instrument is also called a current probe or a current meter.

A current clamp gets used to appraise and determine the magnitude of the current flowing through a conductor. It gets done in terms of the number of amperes. Generally, the device computes the alternating current (AC) that moves within the conducting medium. Nonetheless, a few distinctive and unique current clamps exist. They can assess the magnitude or value of the direct current (DC) instead.

A current clamp also has the ability and capability to measure the phase and waveform of the flowing current. It is possible when the instrument works together with a few specific devices.

What are the Different and Distinct Applications of a Current Clamp?

source: thekatynews.com

A current clamp proves highly beneficial in particular cases. For instance, it gets used frequently when the live power supply to a specific device or conductor cannot get cut off. It may be due to the unfeasibility of the scenario or some circumstances that make it impossible to do so.

Nevertheless, a current clamp works in those scenarios as well. It implies that the instrument is safe for use even when a device remains active and receives a direct and continuous current flow and supply.

A current clamp can get used across various sectors, fields, and domains due to its advantageous features. It can get associated with various electrical, commercial, residential, and industrial appliances. A few common and notable uses of the current clamp consist of the following:

- A current clamp aids in the fixing and restoration of the specific connections of an existing electrical device or system. It does not need to cut off or disconnect the principal or active power supply connected to the conducting medium.

- It helps during troubleshooting and installation of any problematic and new appliances.

- A current clamp finds application during routine tests and maintenance procedures. It helps oversee the overall functioning and working condition of electrical circuits. In addition, it checks for the chances and possibilities of hidden and underlying problems.

- It helps estimate and gauge the leaks and interference associated with electrical devices and circuits. They can occur in the EMC (Electromagnetic Compatibility) range.

- A current clamp helps compute the current capacity and flow rate. It can do so for distinct circuits and connections at the distribution panels.

- It aids in executing precise readjustments and upkeep procedures. They remain related to malfunctioning, problematic, and faulty devices and appliances. On top of that, it handles and deals with instruments having a high susceptibility to damage and hazards.

How Does a Current Clamp Differ from a Multimeter?

source: gmw.com

Unlike popular belief, a current clamp and a multimeter have significant differences. The confusion may arise due to the resemblance in the functioning of the two devices. Nevertheless, a few specific distinctions set them apart lucidly.

A few points of difference between a multimeter and a current clamp consist of the following:

- Construction and Appearance

A current clamp comes with protrusions that resemble jaws. They get wound around the conducting medium like a wire, pipe, etc. This component remains absent in a multimeter.

The jaws of a current clamp allow for measurements without direct contact with the conductor. It measures the ampere reading and shows the final results on the display screen. In addition to that, a current clamp may possess connecting probes. They permit the instrument to accommodate various measurements and operate similarly to a multimeter.

A multimeter has a dial and a display. It allows for setting the ranging to either manual or automatic. Furthermore, it has a selector knob to measure resistance, voltage, and current. A few advanced models can also compute capacitance, frequency, transistor tests, and other parameters. The probe aids in calculating varying voltage and current values or magnitudes.

- Measurement Conditions

source: gmw.com

A current clamp measures the amperes while the conducting medium or electrical appliance has access or remains connected to a live power supply. Thus, it can get operated with active instruments. In other words, it can work while the devices remain in their useable and operational form.

However, a multimeter cannot do so. It requires the power supply to get cut off before starting the measurement process. Otherwise, the computation procedure can result in severe safety and hazard issues.

- Measurement Parameters

A clamp meter gauges the alternating current value passing through a conducting medium. It uses the electromagnetic induction principle, where a magnetic field gets created within the conductor when a current flows through it. It gives the corresponding ampere reading and value. Nonetheless, a modern current clamp has features to assess other parameters.

A multimeter, on the other hand, can compute various parameters. It consists of the voltage, frequency, resistance, capacitance, temperature, direct current, and alternating current.

- Measurement Value Accuracy

source: techtownforum.com

A current clamp gives exceedingly accurate results, having only about 2% discrepancy. Some specialty models can reduce them to as low as 0.5%. It stands true for current reading values up to approximately 600 A.

A multimeter also gives precise results. However, its inaccuracy stands at about 3%.

- Usage Safety

A current clamp has a higher usage safety than a multimeter, even though the former operates when the conducting medium remains connected to an active power supply. It can get owed to the instrument’s non-contact functioning mode.

However, a multimeter has to get used by connecting the probes at two specific points or areas on the circuit. They have a high voltage passing to them. Thus, direct contact can prove hazardous. For that reason, the power supply has to get cut off before the device can get used.