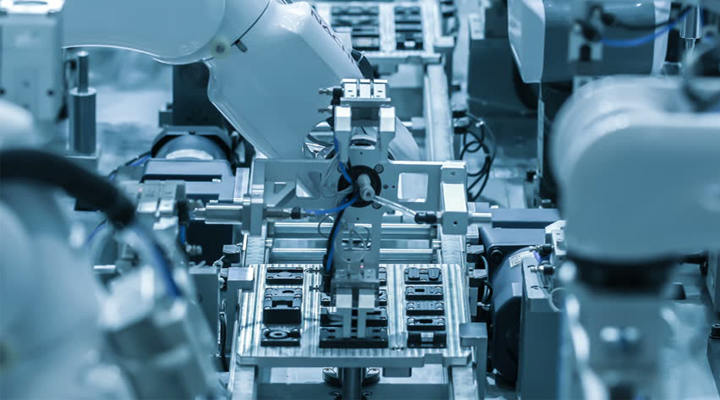

In the fast-paced landscape of modern manufacturing, the transition to automated production has become significant for businesses that seek to stay competitive and efficient. This evolution goes beyond mere technological adoption; it represents a paradigm shift in how industries approach production processes. Let’s talk about the five key benefits of embracing automated production.

Automated production refers to the use of machinery, robotics, and advanced technologies to perform manufacturing tasks with minimal human intervention. This transition marks a departure from traditional manual processes, offering enhanced precision, efficiency, and scalability.

The journey from manual labour to automated production is a testament to the relentless pursuit of efficiency and innovation in manufacturing. As technology advances, businesses are compelled to reevaluate their production methods to remain at the forefront of their industries.

source: pinterest.com

Automated production is more than a trend; it is a transformative force shaping the future of manufacturing. From automotive plants to electronics assembly lines, businesses across sectors are realising the manifold benefits of automation.

One of the primary benefits of automated production is the streamlining of manufacturing processes. Automation reduces the time required for production tasks, which leads to quicker turnaround time with increased output.

Unlike human workers, machines do not need breaks or rest. Automated systems can operate 24/7, ensuring continuous production without interruptions. This capability is precious for meeting tight deadlines and managing high demand.

Automated production ensures a high level of precision and consistency in manufacturing. This minimises errors and variations, resulting in products of superior quality and reliability.

source: pinterest.com

By automating repetitive and labour-intensive tasks, businesses can significantly reduce labour costs. This reallocation of resources allows companies to invest in skilled workers for tasks that require human expertise.

Automated production minimises the risk of human errors, which can be costly in terms of both time and materials. The reduction in errors contributes to cost savings and enhances overall operational efficiency.

Automated systems optimise the use of raw materials and resources. They can precisely measure and dispense materials that will further assist in minimising waste and contribute to a more sustainable manufacturing process.

In a dynamic market, the ability to adapt quickly to changing demands is a competitive advantage. Automated production systems can be easily reconfigured or programmed to produce different products, allowing businesses to respond rapidly to market trends.

Automated systems are inherently scalable. As production needs increase, businesses can scale up by adding more computerised units, ensuring that the manufacturing process grows in tandem with demand.

Automation facilitates the production of customised products with ease. Manufacturers can adjust parameters and settings to meet unique customer requirements, providing a competitive edge in a market driven by personalisation.

source: pinterest.com

Automated production is particularly beneficial for handling hazardous tasks that pose risks to human workers. Robots and machines can undertake tasks involving toxic substances, extreme temperatures, or other dangers without jeopardising human safety.

By automating repetitive and physically demanding tasks, businesses can enhance the overall well-being of their workforce. Employees can focus on more meaningful, skill-based activities, reducing the risk of injuries and job-related stress.

The shift to automated production doesn’t replace human workers but rather transforms their roles. Human-machine collaboration becomes central, where workers oversee, program, and maintain automated systems, fostering a safer and more engaging work environment.

As businesses embrace the benefits of automated production, it’s crucial to consider the energy aspect of these advancements. Partnering with reputable energy brands ensures that the transition to automated manufacturing aligns with sustainable practices. Clean and reliable energy sources contribute not only to environmental conservation but also to the overall efficiency and resilience of automated production processes.

The benefits of transitioning to automated production extend far beyond the factory floor. From cost savings to enhanced safety and adaptability, automation reshapes how businesses approach manufacturing. Embracing the future of automated production isn’t just a technological upgrade; it’s a strategic move towards efficiency, competitiveness, and sustainability.