If you are looking for a quality metal fabrication company for your next custom project, there are a few key points you should consider. Finding out what a company is capable of doing is extremely important before going ahead and finalizing things.

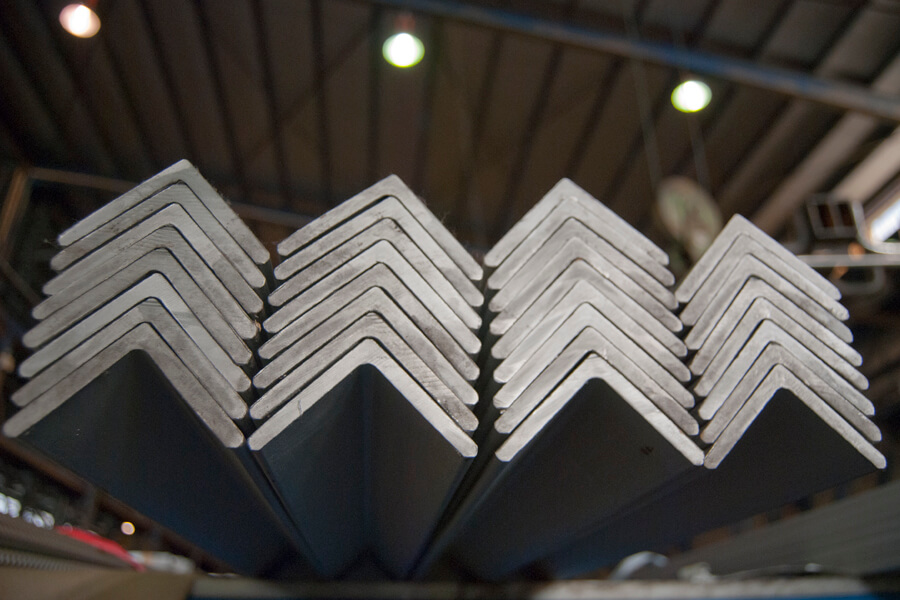

You must know that every shop is set up differently to handle the needs of its primary customer base. Some of these shops specialize in fabricating products which include molding them into various metal angles for specific industries which include structural, medical, aerospace, etc.

Experienced and skilled fabricators are a must. They know how work is done and thus they will ensure great specifications and detailing for your products.

Source : bbdsteel.co.za

When you think of starting to work with a new fabrication shop, the biggest set back will be that you won’t be aware of the work quality of the company you are working with unless you get to know the end results. Thus, it is important to go through the entire merchant website to have a look at the pre-designed pieces which are up for sale. This will give you an idea of the work quality of the company and then you can decide whether you like it or not. Most metal fabricators will show some of their projects for you to look at. Others are very specific in their offering. You should not have any issues with those metal fabricators.

Source : alliedsteel.com

Word of mouth also plays an important role in conveying the reputation of the business. Thus, you can also pay attention to the reviews of customers who have worked with the company before. The company must make sure that the product goes through a final inspection before the customer is even notified.

Structural steel fabrication must be performed by qualified steel fabricators only. It is important to use proper technique while fabricating the metal otherwise it can affect the overall appearance of the product. The fabricator must also ensure the type of material and quality used.

Source : teelplanp.com

One must know that different types of steel have different carbon levels. This affects the tensile strength of the metal and determines how easy it is to weld or mold them. A quality assurance inspector can confirm that the actual alloy composition of the steel being used matches with the required specifications which are pre-determined by the customer.

One of the main benefits of choosing custom metal fabrication services is the product has been customized as per your your need. Thus, it will have the ability to withstand the stresses of your application. When metal products are produced in bulk, they are designed as per general standards. Whereas, when you go for custom metal fabrication the sheet metal will be made of an alloy which will be resistant to temperature, chemicals and various other factors involved in your process. You can check out exact details of metal stock here.

Source : nexcesscdn.net

After a fabrication project has been completed, the ability to look back at material information is highly important. Customer must sure that their metal fabricator does their due diligence when they receive raw materials with logging and inspecting.

You can ask your fabricator about the quality standards and procedures that the fabrication company uses to create your product.

Source : acerinox.com

Quality is an extremely important aspect when it comes to mid to mega custom metal fabrication projects. You should be able to ask the right questions or be able to recognize common steel qualities by doing some research on your own. This is one way to ensure that your fabrication projects are being completed with high-quality materials and in a detail-oriented environment.

For further information, you can visit www.metalscut4u.com