Sheet metal worker jobs introduce one to a career where one can learn about master crafting. It also equips an individual to a diverse skill set that will be helpful for his/her everyday life. So if you are a sheet metal worker and you have to get yourself involved with sheet metal cutting tools in your day-to-day life, knowing about the safety measures of these tools is a necessity.

As the job deals with sharp and hot machines it is really impotent to follow some safety measures before, after and while using the sheet metal tools. This post talk about safety measures that work on sheet metal bending machines.

Quick Safety Clothing Tips:

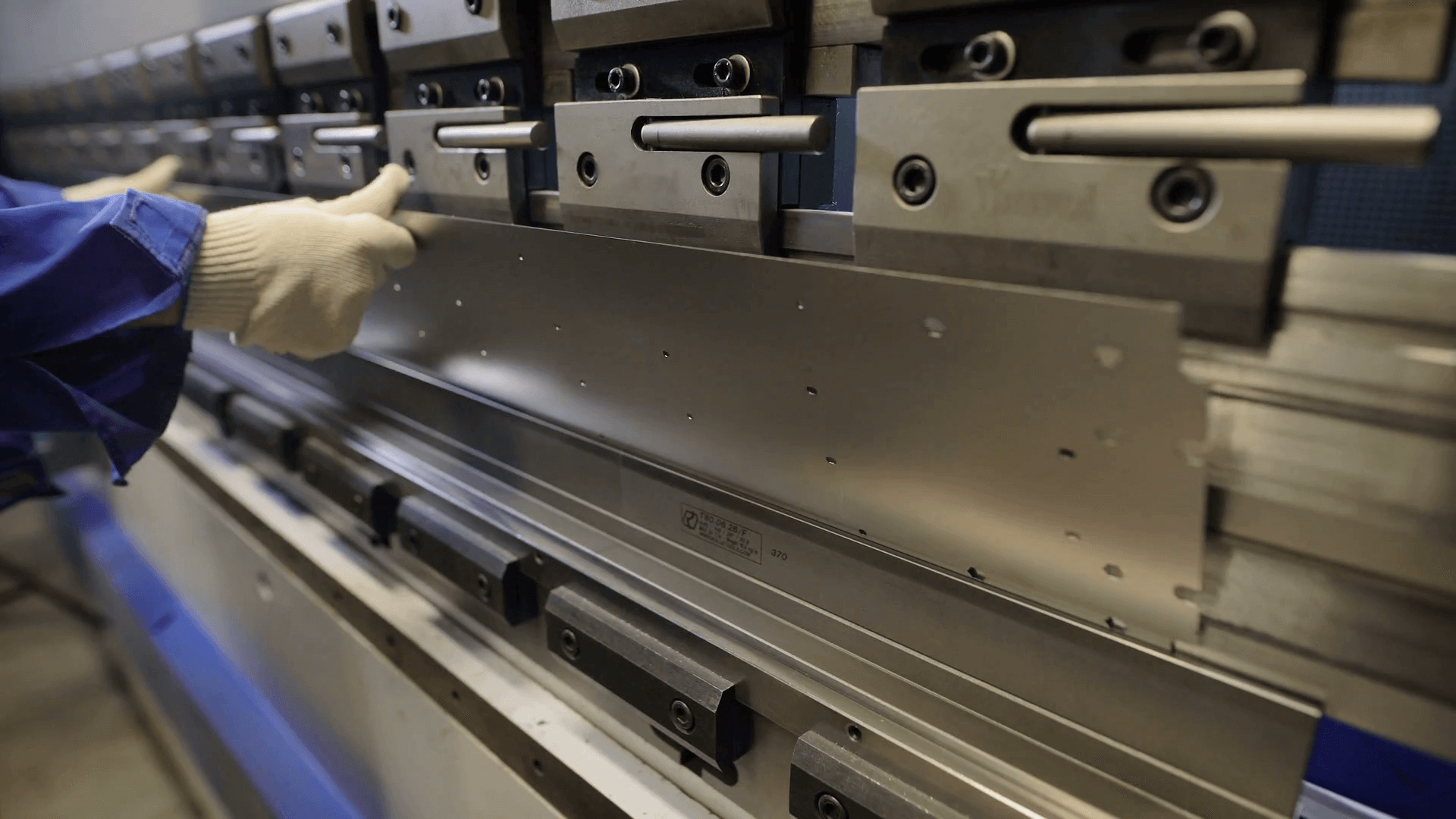

● Never forget to wear Safety Gloves. Safety Gloves are the most important equipment as the hands of a worker are directly involved in holding the machines. It helps to protect hands from sharp materials. If you’re working with some chemical solutions, swap your safety gloves for strong nitrile disposable gloves. Nitrile disposable gloves provide better protection from chemicals — especially liquid chemicals — and can easily be thrown away after use to avoid contamination.

● Boots are highly recommended to be used in such workplaces. There’s a high chance of stepping on sharp equipment while working. So to prevent any injuries on one’s feet one must wear boots to be secured.

● Metal smithereens can be harmful to your eyes and it also can lead to blindness. So, to prevent this problem Goggles should be used while working on sheet metal tools.

● Hard Hats are also required as it will help to keep your head protected.

● You should not wear jewelry or loose clothes. Also, tie your hair up if you have long hair. These may get stuck in the machines and cause serious damage to one’s physic.

Understanding the Machine and its Usage:

Source: cloudfront.net

Sheet metal machines are not machines like mobile phones or desktops that we can experiment on it and develop our knowledge on its usage. It’s a machine that needs safety precautions before even coming near to it.

So if you haven’t operated a sheet metal bending machine before you need to know about it first. One needs to be properly trained before working on it. Training sessions from a skilled and experienced worker is beneficial in this case. Also one can go through the manual script to know the functioning of the machine better.

Paying Attention is a Must:

source: cloudfront.net

Workers need to be in their full concentrated and cautious stage while working on the sheet bending machines. As this work deals with sharp, large and hot tools your waywardness state might lead you to get burnt, cut or to other injuries. So, to avoid getting hurt you have to be very careful when you go near the sheet metal machines and use these tools.

A Quick Checkup of the Tools Before Usage:

Source: www.jmaxengineering.com.au

Inspection of the sheet metal tools and machinery is very important before using it. It should be examined properly that the tools are in good condition or not. You also need to ensure if the moving blades and other parts are properly shielded or not before starting the machines. If You want more information about tools and machinery must-visit Tools Tastico.

Security of Products:

Source: thefabricator.com

The right amount of security should be maintained while using sheet metal machines and other metal manufacture materials. Raw materials, tools, and final products should be properly handled. The machines should be kept warm in cold weather and low temperatures. Also after using the machines they need to be properly turned off and need to be kept in a good place so that these tools don’t get damaged or rusted.

Clean and Organized Workplace:

Source: www.snipsmag.com

It is necessary to clean up the place after being done with the usage of the tools or else you can get hurt by the sharp bits of the metal sheets. Also in a messy haphazard place, it is hard to find materials and it causes wastage of time. The workplace should be organized. The sharp tools should be kept in one space, the laser tools in other also the smaller tools can be kept in toolboxes. There should also be a place for keeping working cloths. Accidents occur frequently in a messy place. So, one must clean up all the scarp to avoid the risk of injuries.

Some Other Quick Tips:

● Always keep your back straight while working to avoid back pain.

● Always hold your metal sheet in the proper way and proper angle. Before starting the procedure of sheet metal bending do ensure that the sheet is parallel to the bender.

● If you get injured, you should not start working again before getting fully recovered.

● Rotating tasks can help to avoid fatigue.

● You may need to stand, climb, bend and squat for long periods while working on the sheet metal tools. You may also need to crawl into tight spaces for installations. So, keeping yourself healthy and fit is required.

● Even if you’re wearing gloves you should never run hands over a sharp cut.

● While working with wet metal sheets you should be extra cautious and careful.

● The workplace must store at least one first aid box as accidents can happen anytime and this box will help to give primary medical care to the injured individual.

● To get the best result from your machine you are recommended to warm it up first. This can be done by allowing your machine to operate for a few minutes on its own. This also reduces the chances of getting yourself stressed.

● Clean yourself up after you are done with your job for a day. Even if you were wearing gloves it is necessary to wash your hands up thoroughly after a day’s work.

Safety should always be the first concern while one work as a sheet metal worker. So, to remain careful and to avoid potential dangers one should follow these steps thoroughly and sincerely.

Don’t forget to visit www.toolsspecialist.com before you leave:).