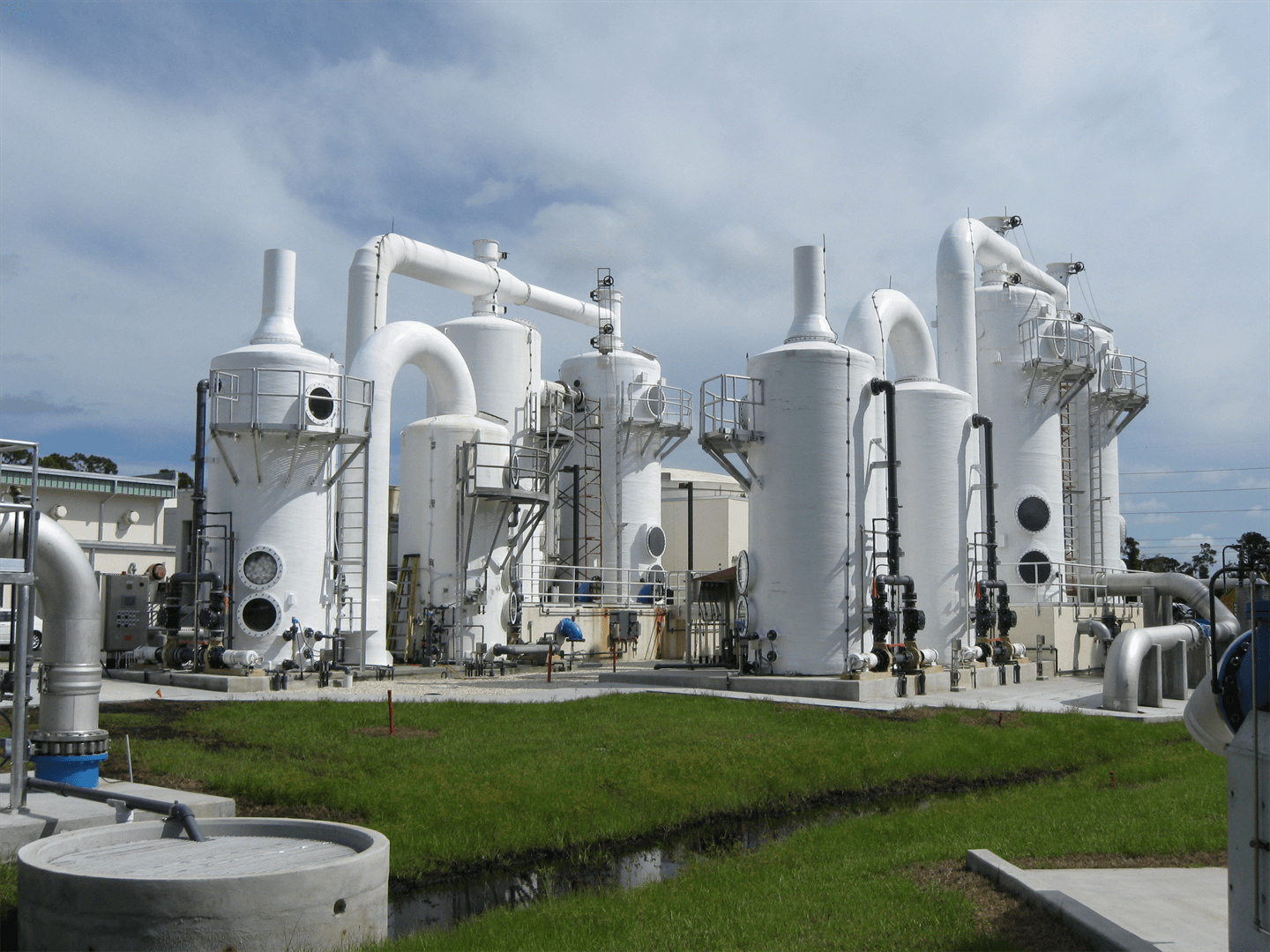

A wet scrubber is a device which controls the air pollution and also helps in removing the acid gases and PM which are difficult to remove in their dirty form. They are generally used during the tasks like chemical production, industrial boilers, and metal processing, etc. The polluted particles are removed through the process of impaction, diffusion, and absorption. The centrifugal technology is used to ensure that air in the industry is properly cleaned. In this article, you will read about the different types of the wet scrubbers.

Types of Wet Scrubbers:

1) Ammonia Wet Scrubbers:

In chemical industries, there are the high amount of ammonia gas emissions, so all the manufacturers of these companies are required to control and remove the ammonia gas emissions. Ammonia wet scrubbers provide the best in-house control from these types of emissions. In most of the cases dilute sulfuric acid is used to nullify the ammonia from the air. You can get a customized wet scrubber system from certified manufacturers so that you can get long-term performance.

2) Chemical Scrubbers:

The chemical scrubbers are popularly known as gas scrubbers and these wet scrubbers are used to remove gas particles from the air. These gas particles are present in the form of ammonia and sulfur. The wet scrubber operates in the form of scrubbing liquid as they absorb the gas pollutants. These types of wet scrubbers are generally used in the metal finishing process and various other industrial operations. These types of chemical scrubbers include different design considerations like removal efficiency; pollutant targeted, and process conditions.

3) Dust Scrubbers:

The system of dust scrubbers is not complicated like other wet scrubbers and they use water to remove the dust from the waste gas stream. Its design is dependent on different considerations like the type of the dust to be removed, the removal efficiency, flow rate and temperature of the waste gas stream, location of the scrubbers whether outside or inside and lastly it also depends on dust size distribution. You should contact the manufacturer who manufactures these scrubbers to choose the right one for you.

4) Chlorine Scrubbers:

We know that chlorine is a by-product which we get from the extraction of various chemical reactions. In case of chlorine scrubbers, the removal efficiency is the very important thing to consider as these scrubbers use a multi-stage removal technique. It depends on certain factors like the amount of liquid re-circulated and the design of the system. The Chlorine is a poisonous gas and this Chlorine wet scrubbers use the multi-stage removal technique to remove this gas from the gas stream.

5) Venturi Scrubbers:

If you have a gas stream that contains moisture and high temperature then Venturi Scrubbers are suggested to remove the particulate from the waste gas stream. They can remove both the gas and the particulate. A scrubbing vessel is used in order to remove the gas and particulate. A system fan and mist eliminator are also used to control the particulate. Venturi scrubber is generally used in corn processing, food manufacturing industries, and metal finishing operations etc. The dust particles are removed in liquid droplets and then are separated from a waste gas stream.

6) Sulfuric Acid Wet Scrubbers:

Sulfuric acid is a toxic by-product and it needs to be removed from the emissions. The multi-stage technique is used to remove this highly toxic gas from the gas stream. These types of wet scrubbers can commonly be used in removing the water vapor.

Conclusion:

Wet scrubbers are the best thing to remove the dust and gases from the gas stream and they act as a pollution system to control these dusts to enter into the air. They mainly depend on the considerations, such as its control removal efficiency, etc and they include a mist eliminator, system fan and exhaust stack. You should install these wet scrubbers in your industries according to your requirements but do not forget to consult a manufacturer or professional before buying any wet scrubber.